Different types of underlay are available on the market that are compatible with hardwood flooring. Underlay acts as a middle layer between the subfloor and the hardwood floor to help thermal resistance and/or sound proofing. Under no circumstances should an underlay be used to level an uneven subfloor. If you are installing onto an uneven concrete subfloor, the surface should be self levelled prior to the floor installation.

Thermal resistance and sound proofing

To provide thermal resistance, a good tog rating for underlay, when you are not using under floor heating, is 1.0 tog. If you are using under floor heating you should use a special under floor heating underlay with a low rating of 0.35 tog. Sound proofing reduction is rated on minus decibels. A good quality sound proofing underlay would have a rating of approximately -25 decibels and a standard DIY underlay would be around -19 decibels. The thickness or colour of the underlay makes no difference to the thermal resistance or sound proofing. The five most commonly used types or underlay are:

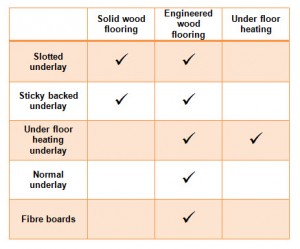

Slotted underlay

A slotted underlay can be used with solid wood flooring or engineered wood flooring. Glue is applied into the slots of the underlay using a barrel gun which helps make the application quick and mess free. The wood flooring is then fixed on top and held to the subfloor by adhesive through the slots. Using this method ensures a secure, long lasting installation whilst also providing additional sound deadening.

Sticky backed underlay

Sticky backed underlay can be used with both solid wood flooring and engineered wood flooring. The underlay is laid onto the subfloor, and then the plastic backing is gradually removed, to reveal a sticky layer as the floor is being laid. The flooring planks are stuck securely down to the underlay. There are different strengths and qualities of sticky backed underlays on the market so ensure the one being used is strong enough for your application and width of board; as a general rule, the wider the board the stronger the adhesive needs to be on the underlay.

Standard underlay

Standard wood underlay should only be used with engineered flooring. The engineered wood should then be floated over the top of the underlay and should be either glued or clicked together at the joints. Some standard underlay usually has a built in moisture barrier which prevents moisture from the concrete or screed sub floor attacking the engineered flooring installed on top. It is always best to ensure your sub floor is dry by using a floor moisture meter before laying the underlay as the moisture will lay underneath the underlay and could move sideways into your walls.

Under floor heating underlay

Under floor heating underlay is available with much lower tog ratings (0.35 tog). This ensures the temperature from the under floor heating system is not compromised and does not malfunction. Engineered flooring must be used with under floor heating and can be loose laid (floated) over the underlay by gluing or clicking the planks together.

Fibre boards

Fibre boards can only be used with engineered wood flooring and are used to help take out small undulations or unevenness in floor boards, providing a firm foundation for any engineered floor.

Below is a chart that shows the correct type of underlay for each flooring type:

For questions relating to any Ambience Hardwood Flooring products, telephone 0116 2741050 or email mail@ambiencehardwoodflooring.com. Thanks for reading.