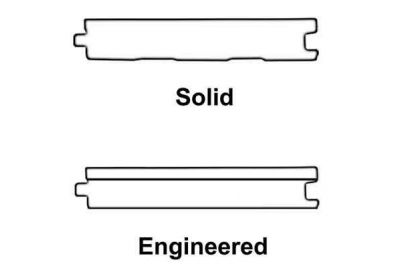

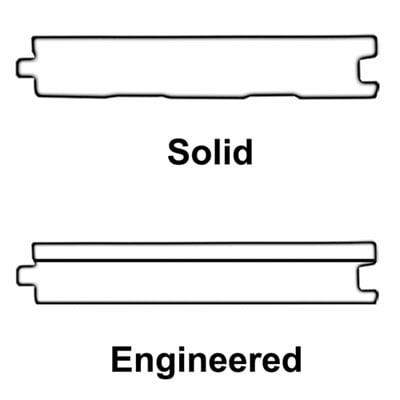

The main difference between solid wood flooring and engineered wood flooring is the construction of the planks, which then affects how and when they can be used.

Construction of the planks

Solid wood flooring is a solid piece of wood cut out of a tree trunk, then planed, machined and sanded into planks of flooring. It is available in different thicknesses ranging from 15mm to 22mm, and comes in random lengths with a tongue and groove (see our 'wood flooring guide') fitting system. Solid wood flooring can either be unfinished or prefinished. Unfinished floor is raw material, and will need sanding and sealing with oil or a lacquer. It can also be stained to individual colour preference. A prefinished floor is already stained, oiled or lacquered and is available in a variety of different stains and finishes.

Engineered wood flooring is made up of multiple layers of wood. The top layer, or wear layer, is the chosen species of wood, for example, Oak or Walnut (this wear layer must be thicker than 2mm, otherwise it is classed as veneered wood flooring, rather than engineered). There are two types of base layer for engineered planks; a plywood base or a 3-ply block construction. The plywood base is a layer of plywood glued to the bottom of the wear layer. Alternatively, a 3-ply block construction has a middle layer, usually Hevea or Eucalyptus, which is glued at 90 degrees to the grain of the wear layer. It then has a base of plywood. Both types of engineered wood flooring are available in different thicknesses ranging from 12.5mm to 22mm, and usually come in fixed lengths with either a tongue and groove or click fitting system. Like solid wood flooring, engineered wood flooring can either be unfinished or prefinished. Unfinished floor is raw material, and will need sanding and sealing with oil or a lacquer. It can also be stained to individual colour preference. A prefinished floor is already stained, oiled or lacquered and is available in a variety of different stains and finishes.

Engineered wood flooring should not be mistaken for laminate flooring, which is, essentially, a picture of wooden flooring laminated onto high density fibreboard (HDF), not wood.

Usages of solid and engineered wood flooring

Solid wood flooring planks are not stable so must be fixed in position when installed, by either secret nailing, secret screwing or gluing down. They must not be laid loose over underlay and cannot be used with under floor heating. Because it is a solid piece of wood it will expand and contract, so cannot be used in areas where temperature and humidity fluctuates significantly, for example: kitchens, conservatories and rooms with large amounts of glazing. As engineered wood flooring planks are made up of multiple layers, it means they are dimensionally stable and do not need fixing in place - they can be loose laid over an underlay, this technique is also known as a ‘floating floor’.

Engineered wood flooring can be used with various types of underlay, including, soundproofing underlays and thermal barriers. If necessary, engineered wood flooring planks can also be glued down, and secret nailed or secret screwed if the plank is thick enough. Because they are made up of multiple layers, they will not expand and contract as much as solid wood flooring planks, so they can be used with under floor heating, and in areas where temperature and humidity fluctuates significantly, for example: kitchens, conservatories and rooms with large amounts of glazing. Once the floors are laid, they both look the same and it would be almost impossible to tell the difference between solid wood flooring and engineered wood flooring by sight alone.

Durability and life

If the same species of wood is chosen, both solid wood flooring and engineered wood flooring are as durable as each other. This is because the same material is being walked on, and it does not matter that the underneath may be made from something different. On average, floors would need sanding commercially every 5 years, and residentially every 20 years, depending upon the hardness of the species of wood. Solid wood flooring can be sanded down to the top part of the tongue and groove which, on an average 18mm solid wood floor, is approximately 3-4mm. Sanding an engineered wood floor depends on the thickness of the wear layer (ranging from 2mm to 6mm).

For example, an engineered wood floor with a 6mm wear layer can be sanded more than an 18mm solid wood floor. For questions relating to any Ambience Hardwood Flooring products, telephone 0116 2741050 or email mail@ambiencehardwoodflooring.com. Thanks for reading.